Knobs and Totes on all Millers Falls Planes

This page is going to investigate the knobs and totes used on the Millers Falls planes. The knobs and totes will be displayed based on their size and the style. From 1929 through 1969, the company only used three different size totes and two different size knobs. Using only the shape of the tote, there were two different shapes or styles up to 1965 and a new third style that would finish out the plane line.

The knobs and totes were made from three different wood species, Cocobolo, Goncalo Alves, and Beech on all Millers Falls brand planes and the rebrand planes Millers Falls produced.

Measuring the wood on these planes is the easy part of this page. The difficult part is identifying the finish used on the wood. This aspect will continuously be updated as new information becomes available.

Bench Planes

The two pictures below show where the measurements were made on the wood. It is important to understand that not all the knobs and totes have the exact measurement on a given size and style. Measurement can vary an eighth of an inch on any of the parameters possibly because of slightly different calibrations between the different cutting machines.

The size of the knob and tote is based on whether the tote has a tote screw or not. The finishing planes do not have a tote screw and are found on planes such as the No. 8, No. 9 and No. 11. The No. 7 is not in this list because of the unique size and style which puts this plane in a class of its own. The planes with a tote screw are the larger totes and knobs and are found on the No. 10, No. 14, No. 15, No. 18, No. 22 and the No. 24. In 1965, the company consolidated the size and style on the tote and knob putting the same knob and tote on all remaining planes in production.

Bench Plane Totes

The three different styles used on the bench planes can be grouped in years. The first style would range from 1929 through 1952. This would include the type 1, 2, 3 and type 2 second release. The style on the type 4 planes would have a slightly different gripping angle and would see a new wood and finish used. The type 4 was produced from 1953 to 1965. The third and final style would be unique to the type 5 planes only. This style would have a shorter front length and a longer bottom length. The type 5 style started around 1965.

Totes on smoothing planes

|

No. 8, No. 9, No. 11 |

Type 1 - 3 |

Type 4 |

Type 5 |

|---|---|---|---|

| Front Height | 3-3/16" | 3-7/16" | 3-5/16" |

| Back Height | 4-1/4" | 4-7/8" | 4-3/8" |

| Thickness | 15/16" | 15/16" | 15/16" |

| Top Length | 2-5/8" | 2-1/2" | 2-1/2" |

| Bottom Length | 3" | 3-1/16" | 3-9/32" |

| Forward Angle | 122° | 115° | 118° |

| Tote Bolt Angle | 65° | 65° | 70° |

Totes on larger planes with tote screws

|

No. 14, 15, 18, 22, 24 |

Type 1 - 3 |

Type 4 |

Type 5 |

|---|---|---|---|

| Front Height | 3-1/4" | 3-1/2" | 3-5/16" |

| Back Height | 4-1/2" | 4-1/2" | 4-3/8" |

| Thickness | 15/16" | 15/16" | 15/16" |

| Top Length | 2-15/16" | 2-1/4" | 2-1/2" |

| Bottom Length | 3-3/8" | 3-7/16" | 3-9/32" |

| Forward Angle | 122° | 115° | 118° |

| Tote Bolt Angle | 65° ** | 65° | 70° |

** On the early type 1 models, the tote bolt is drilled and tapped at 60°. The totes are drilled at 65°.

Bench Plane Knobs

Only two different size knobs were produced for the Millers Falls planes. The shorter knob on the left was used on the No 7, No. 8, No. 9, No 11 and all the type 5 planes. The knob on the right was used on the No. 14, No. 15, No. 18, No. 22, No. 24 types 1 through type 4 planes with a tote screw.

Knobs on all planes

|

|

Smaller Knob |

Larger Knob |

|---|---|---|

| Height | 2-1/2" | 2-11/16" |

| Width | 1-5/8" | 1-11/16" |

| Waist | 13/16" | 13/16" |

Bolts and Screws Securing the Knob and Tote

There are three distinct types of bolts that secure the knobs and totes on all Millers Falls planes. The type 1, type 2, and type 4 used a double threaded bolt with a brass waist nut. The type 3 used a one piece bolt that is usually blued. The type 5 used a different one piece plated bolt. The type 1 through type 4 larger planes also used a tote toe screw to secure the front of the tote.

Bolt Sizes and Thread Count

|

Knobs and Totes |

Double Threaded Bolt |

Type 3 Bolt |

Type 5 Bolt |

|---|---|---|---|

| No. 8,9,11 Knob | 2-3/16" (12-20) |

2-5/16" (12-20) |

2-5/16" (12-24) |

| No. 8,9,11 Tote | 3-11/16" (12-20) |

3-13/16" (12-20) |

4" (12-24) |

| No. 10,14,15,18,22,24 Knob | 2-3/8" (12-20) |

2-1/2" (12-20) |

2-5/16" (12-24) ** |

| No. 10,14,15,18,22,24 Tote | 4-3/16" (12-20) |

4-3/16" (12-20) |

4" (12-24) ** |

** The No. 10, No. 15, No. 24 were not available at the start of the type 5

Tote Toe Screw is 1/2” long with a 12-20 size - thread count.

Premium Bench Plane Knobs and Totes Features

Type 1 Knobs and Totes

The type 1 knobs and totes have a few differences that separate them from the types with the same styles. The inside of the knob base shows the six marks of the cutting machine that formed the knob. Only the type 1 knobs have these marks. Starting with the type 2, the six marks are replaced with eight grooves on the bottom of the knob. The type 1 knobs also have a small bevel on the inside edge of the knob bolt hole. The same bevel is larger starting with the type 2.The knobs and totes are secured with a double 12-20 threaded bolt and a brass waist nut. There are two different size bolts for the knobs and two sizes for the totes.

Wood - Tropical Cocobolo

Finish - Because cocobolo is a dark wood, the knobs and totes were only sprayed with a clear lacquer.

To the left is the larger knob and tote used on the planes with a tote screw. The No. 8, 9, and 11 used the knob and tote on the right. The No. 7 used the smaller knob on the right.

The four different size threaded bolts with the brass waist nuts.

The four bolts without the waist nuts. When ordering replacement bolts, you need to specify the length of the bolt without the waist nut.

Bottom of the type 1 knob. The six cutter marks are unique to only the type 1 knob.

Type 2 Knobs and Totes

The eight grooves on the bottom of the type 2 knob align with the eight ridges cast into the bed of the plane body. This new feature starting with the type 2 knobs will be used on all planes manufactured by Millers Falls. The bevel on the inside edge of the knob bolt hole has been increased to clear the casting ridges. The knobs and totes are secured with a double 12-20 threaded bolt and a brass waist nut. There are two different size bolts for the knobs and two sizes for the totes.

Wood - Tropical Cocobolo

Finish - Because cocobolo is a dark wood, the knobs and totes were only sprayed with a clear lacquer.

Type 2 are identical to the type 1 except for the bottom of the knob.

Eight groves on the knob bottom to match the ridges on the plane bed. These groves also help prevent the knob from turning while in use.

Type 3 Knobs and Totes

In the forties, cocobolo could not be obtained because of World War II. The company turned to a hardwood it could obtain in its own back yard - birch. Birch was not new in making knobs and totes on planes. The company used birch on the Fulton line and its own Mohawk Shelburne secondary line. The knobs and totes are secured with a single 12-20 threaded blued bolt because brass was scarce in the forties.

Wood - Birch Hardwood

Finish - The finish has not been determined at this time and this section will be updated when the correct finish and procedure for applying the finish are finalized.

Without removing the knob and tote, it is easy to identify a type 3 plane with the birch hardwood. The knob and tote on the left are found on the finish planes. The larger planes will have the knob and tote on the right.

The bolts were blued to prevent rust. These bolts are measured from under the head to the end.

Type 4 Knobs and Totes

Starting in 1953, the company changes the wood used on their planes to Goncalo Alves which is a tropical hardwood found in Central America and South America. A new style is found on the type 4 totes with a different gripping angle and more room at the back of the tote. The knobs and totes are secured with a double 12-20 threaded bolt and a brass waist nut. There are two different size bolts for the knobs and two sizes for the totes.

Wood - Goncalo Alves

Finish - The stain used does not penetrate the wood. It is a finish applied on top of the wood in several coats. It has not been determined at this time and this section will be updated when the correct finish and procedure for applying the finish are finalized.

Goncalo Alves is a light colored tropical hardwood with rich dark grain sometimes referred to as tigerwood. The knob and tote on the left are found on the finishing planes. The tote on the larger planes have a shorter horn as seen on the right tote. The shorter horn is only found on the type 4 totes with a tote screw.

Type 5 Knobs and Totes

Starting in 1964, the company changes the design of the knob and tote so that all existing bench planes used the same knob and tote. All the planes would use a removable tote toe pin to stabilize the tote. To further cut costs, the knob and tote bolts where changed to a standard bolt configuration with a standard 12-24 thread. The company continued to use Goncalo Alves. There are only two different size bolts, one for the knob and the other for the tote.

Wood - Goncalo Alves

Finish - The stain used does not penetrate the wood. It is a finish applied on top of the wood in several coats. It has not been determined at this time and this section will be updated when the correct finish and procedure for applying the finish are finalized.

The knob and tote on the left was removed from a No. 8 type 5 plane. The knob and tote on the right was removed from a No. 14. As you can see, both knobs and totes are identical.

The early type 5 knob and tote bolts had a lock washer and a regular washer under the bolt head. A short time later, the company eliminated the washers and changed the depth at the top of the knob and tote to allow only the bolt head to be recessed.

How The Tote Bolt Angle Was Measured

There are several different ways to measure the angle of the tote bolt. The method described below was used because the protractor, sliding bevel and drill bit were available and I didn’t need batteries.

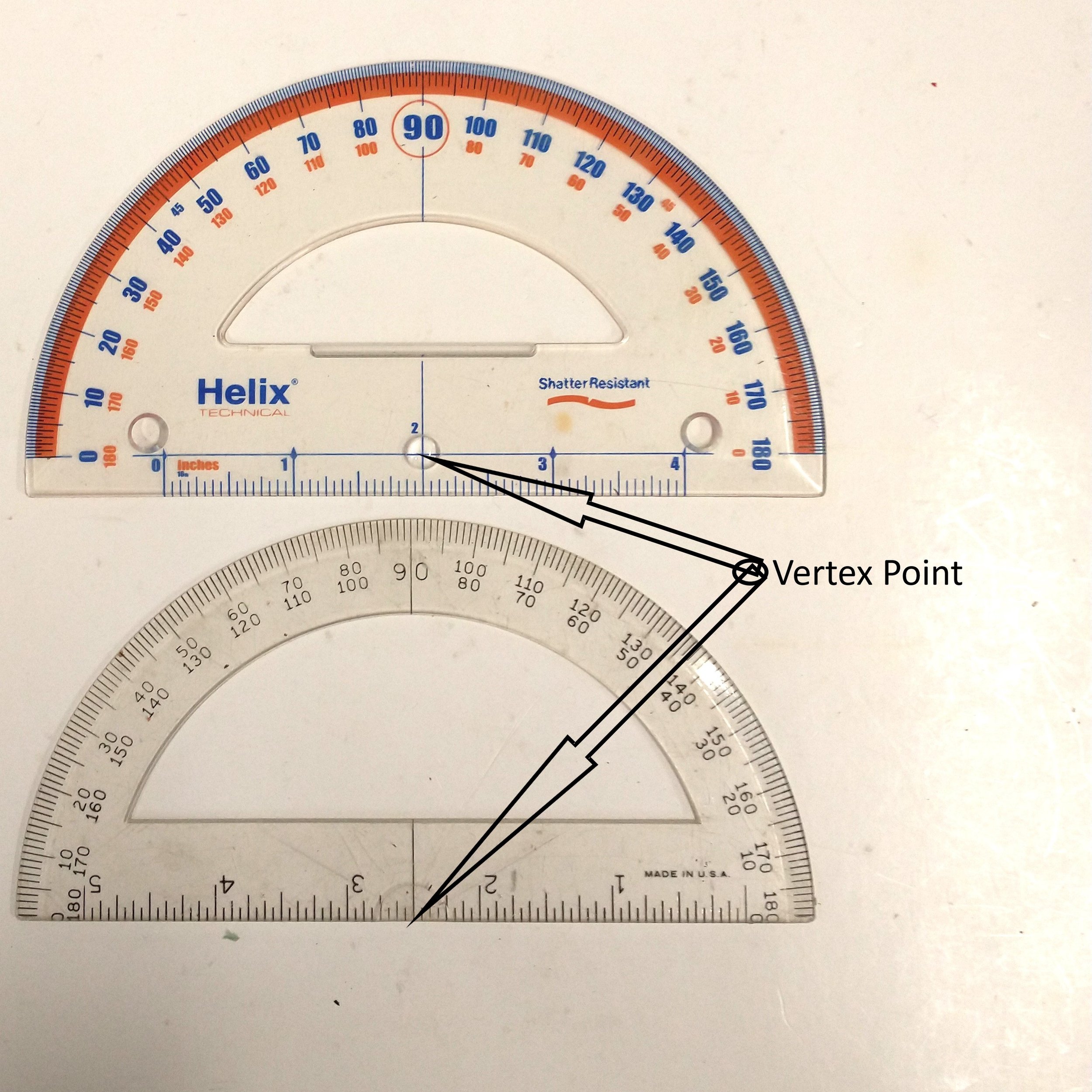

Simple protractor. The top protractor has the vertex point raised off the bottom. The bottom protractor has the vertex point at the bottom. Simply align the vertex point in the middle of the bolt or the edge of a sliding bevel and read the degrees at the top.

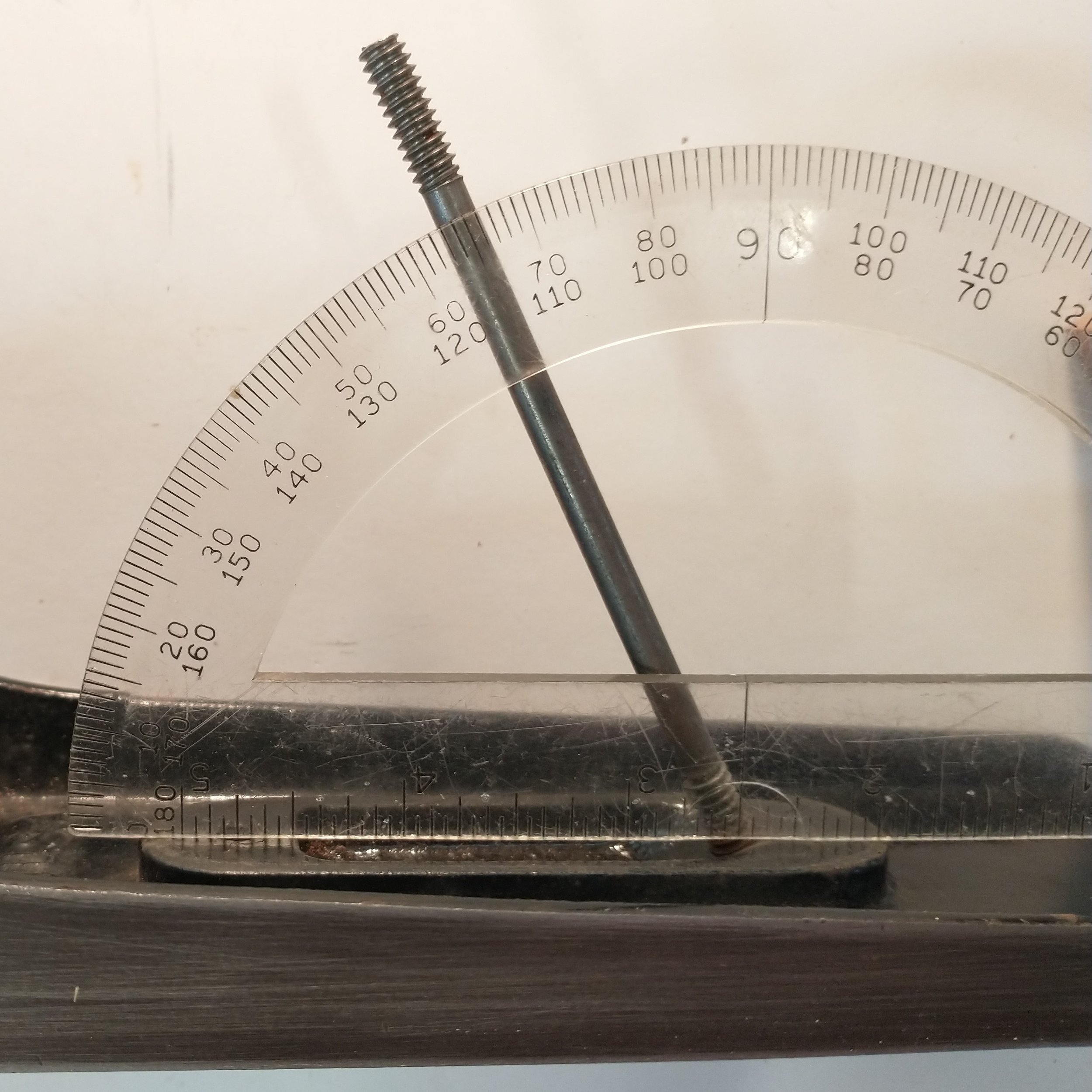

Rest the protractor on the top of the raised tote receiver. Align the vertex point in the center of the double threaded rod. Read the degrees in the middle of the rod.

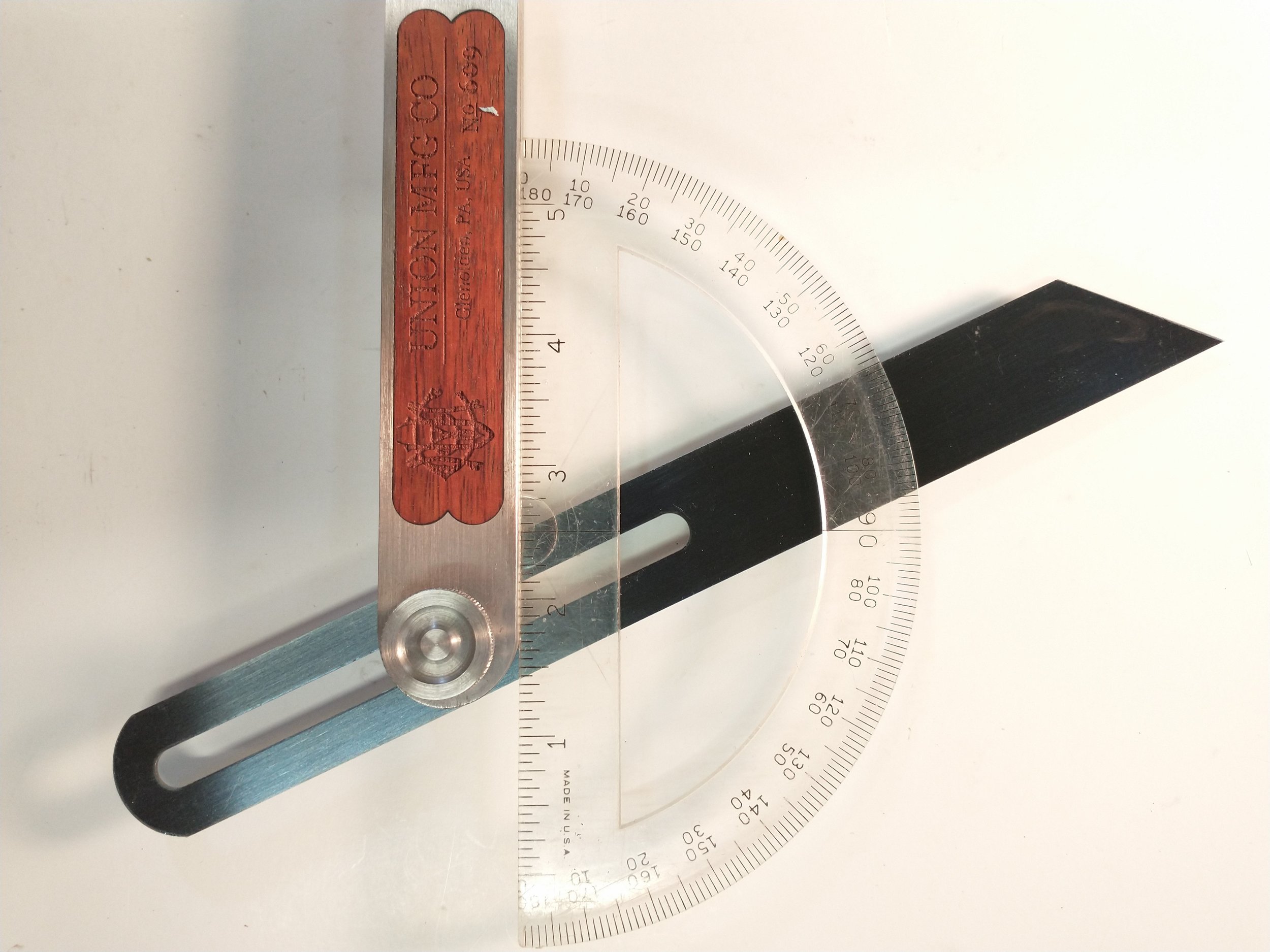

In this example, a 7/32 6" drill was inserted through the hole in the tote. Rest the bottom of the tote on the sliding bevel and adjust the bevel so the edge is in the middle of the drill at the top and bottom.

Align the vertex on the protractor with the sliding bevel.