Premium Bench Plane Study

This type study will list the six types defined in the premium line. Each type will have five sections;

lever cap features

frog /iron features

body/knob/tote features

crossover features

examples of planes

The first three sections will list new or updated features in red and features that transitioned over from the previous type in black.

When a new type was introduced, the factory may have excess parts from the previous type left over. These excess parts were incorporated into the new type line until the supply was exhausted. Actual examples with these “Crossover” features will be shown.

Examples have been found that are outside the common features listed for a given type. This group is not about a crossover plane or a plane where a user has swapped out parts, but factory features on a lever cap, frog , body or iron what cross over one or more types. The section at the bottom titled “Outside The Type Study” will look at examples with uncommon features.

Type 1

Lever Cap

A list of the six lever caps with casting numbers and the size plane the cap was used on;

1-5/8” (332) No. 7

1-3/4” (333) No. 8 and No. 11

2” (334A) No.9 and No 14

2-1/4 (335) No. 15

2-3/8 (336) No. 10, No. 18 and No.22

2-5/8 (337) No. 24

1929 to 1935 Common Features

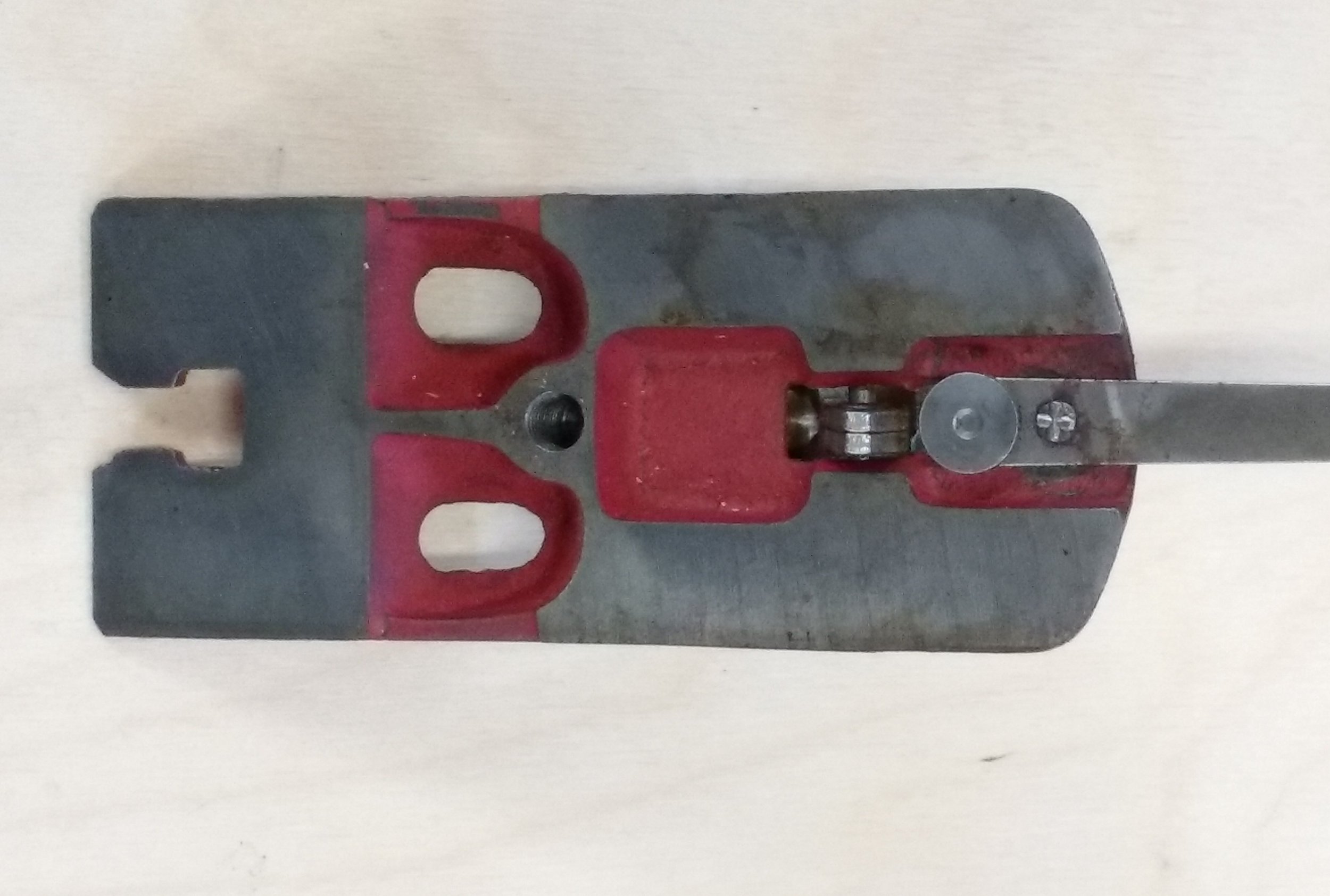

Two piece nickel plated hinged cap with three contact points.

Interlocking tabs on the main upper section to fit into the lower T-section.

Semi-circle containing “MILLERS FALLS” with a red background of the semi-circle.

Back side of lower section contains free hand cast text “PAT. APLD. FOR”.

Large rivet head securing cam lever spring.

Patent number 1822520 approved Sep 8, 1931. Stamped on upper section face starting around 1933.

2” Only - Casting relief inside length is curved.

The two contact pads on either side of the lever cap screw hole applies pressure to the iron securing it tightly against the frog face. The locking tabs between the upper and lower sections are only found on the type 1 lever caps. Another type 1 feature is the large rivet head securing the cam spring.

Millers Falls started producing the hinged lever cap before the patent was approved in 1931. Before the type 1 style ended in 1935, the patent number would be applied to the lever cap face.

Type 1

Frog and Iron

A list of the six frogs with casting numbers and the size plane the frog was used on;

1-5/8” (315) No. 7

1-3/4” (316) No. 8 and No. 11

2” (317) No.9 and No 14

2-1/4 (318) No. 15

2-3/8 (319) No. 10, No. 18 and No.22

2-5/8 (320) No. 24

1929 to 1935 Common Features

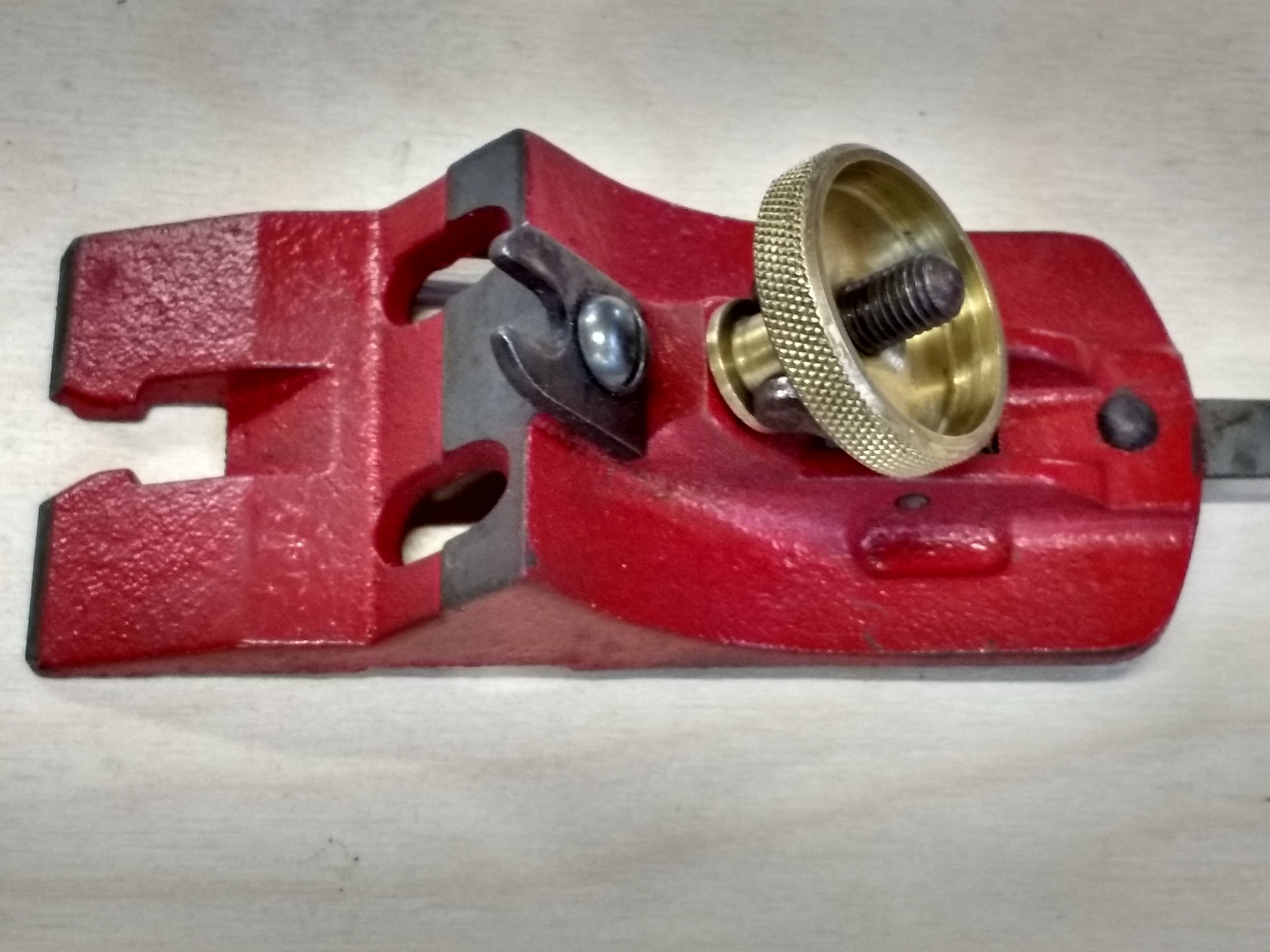

Painted red

Cast iron yoke painted red

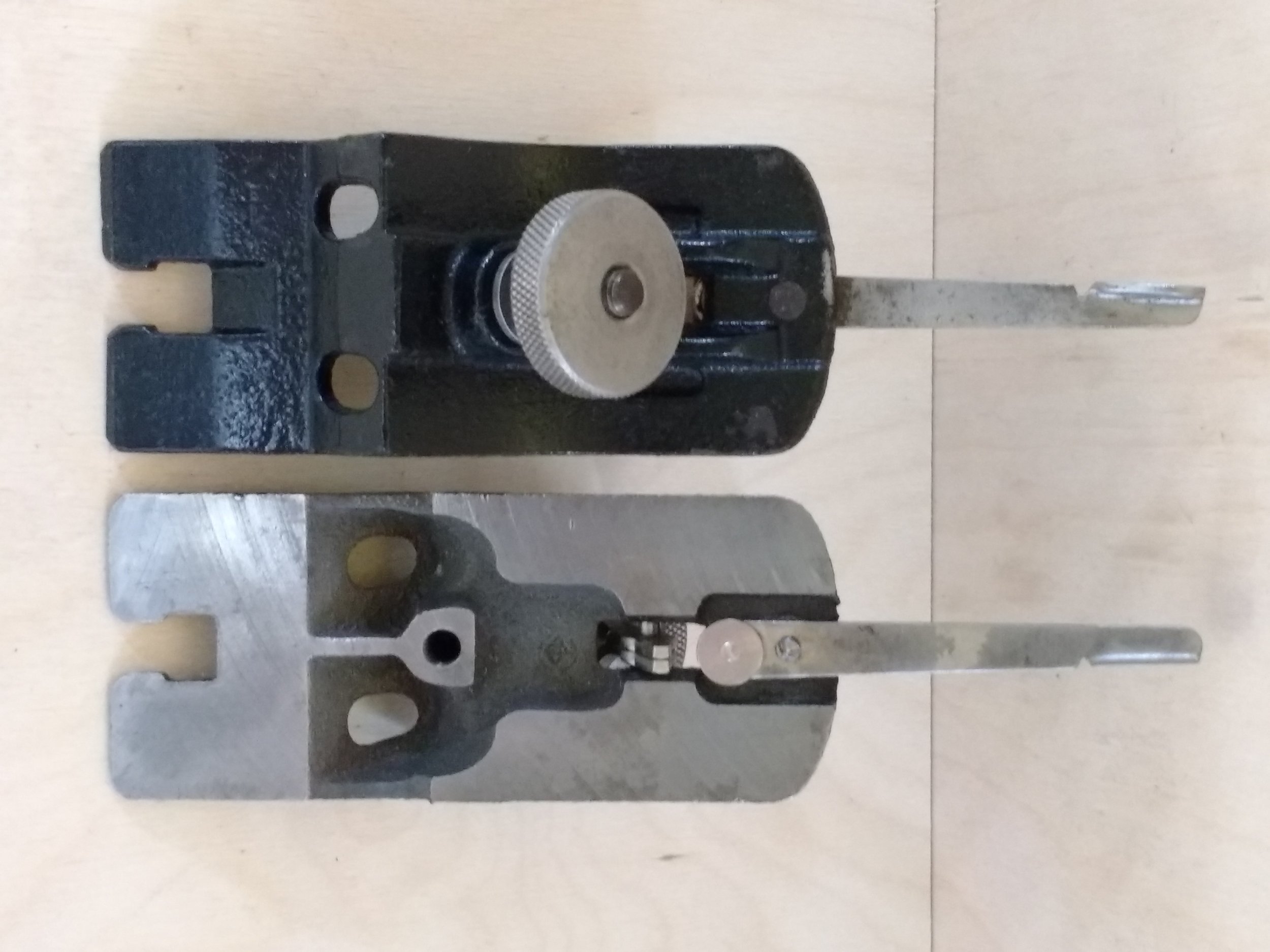

Knurled 9/32-24 brass depth adjusting nut (recessed design)

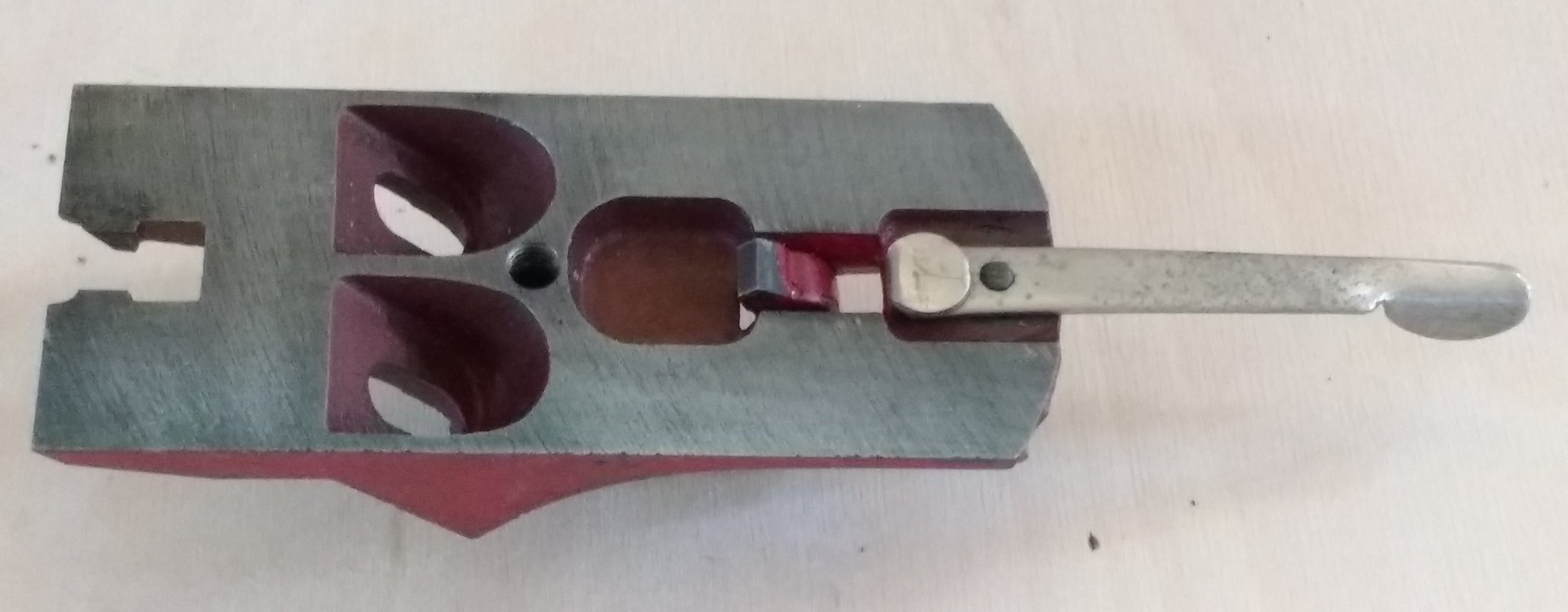

Folded lateral adjustment lever

1-3/4” and larger frogs are configured with a frog adjuster tab/screw. Only the 1-5/8” frog has no adjuster tab/screw.

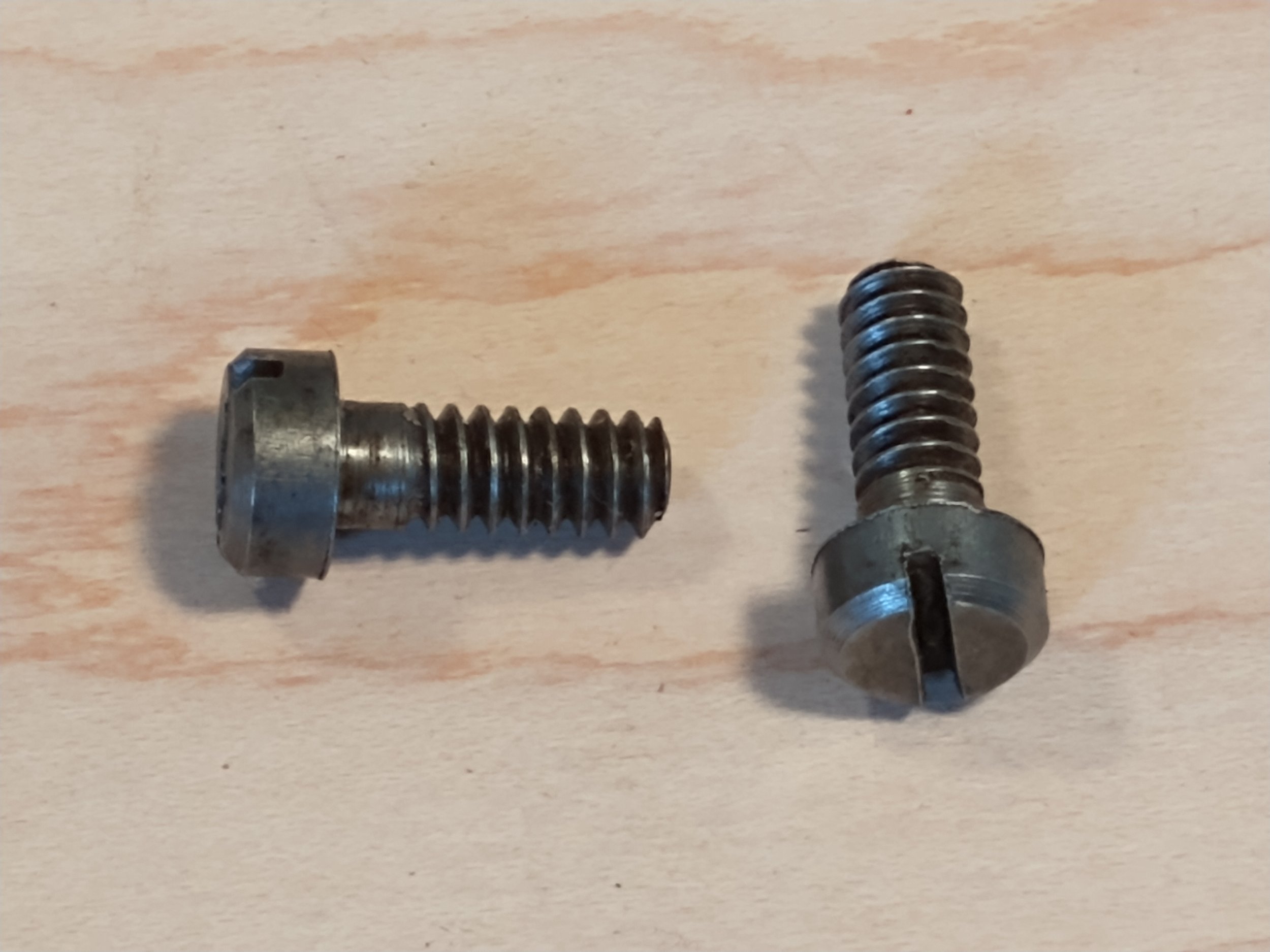

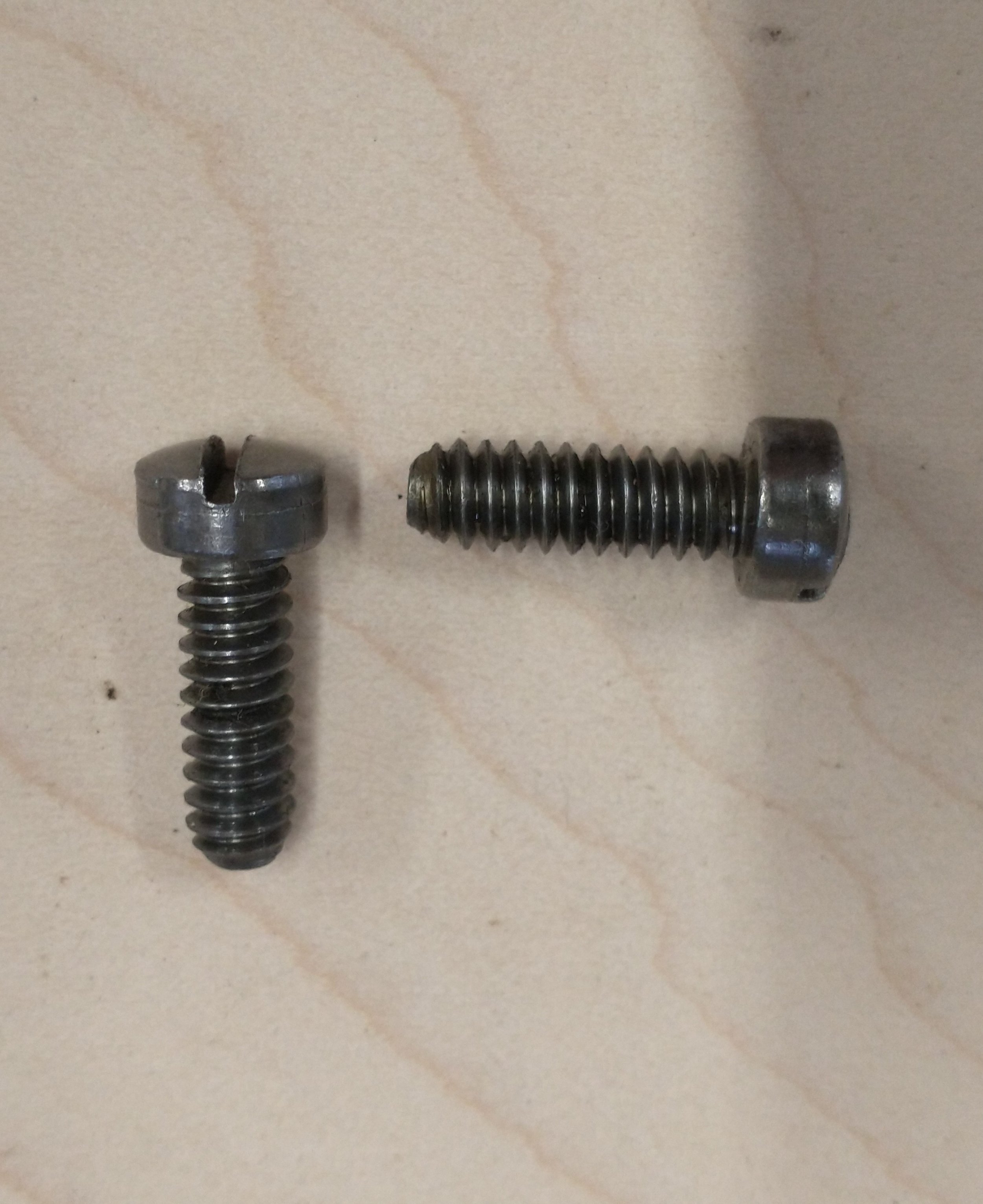

12-20 flat fillister head frog locking screws

Around 1933, extra metal was added around the lever cap screw on the 1-3/4” and 2” face only.

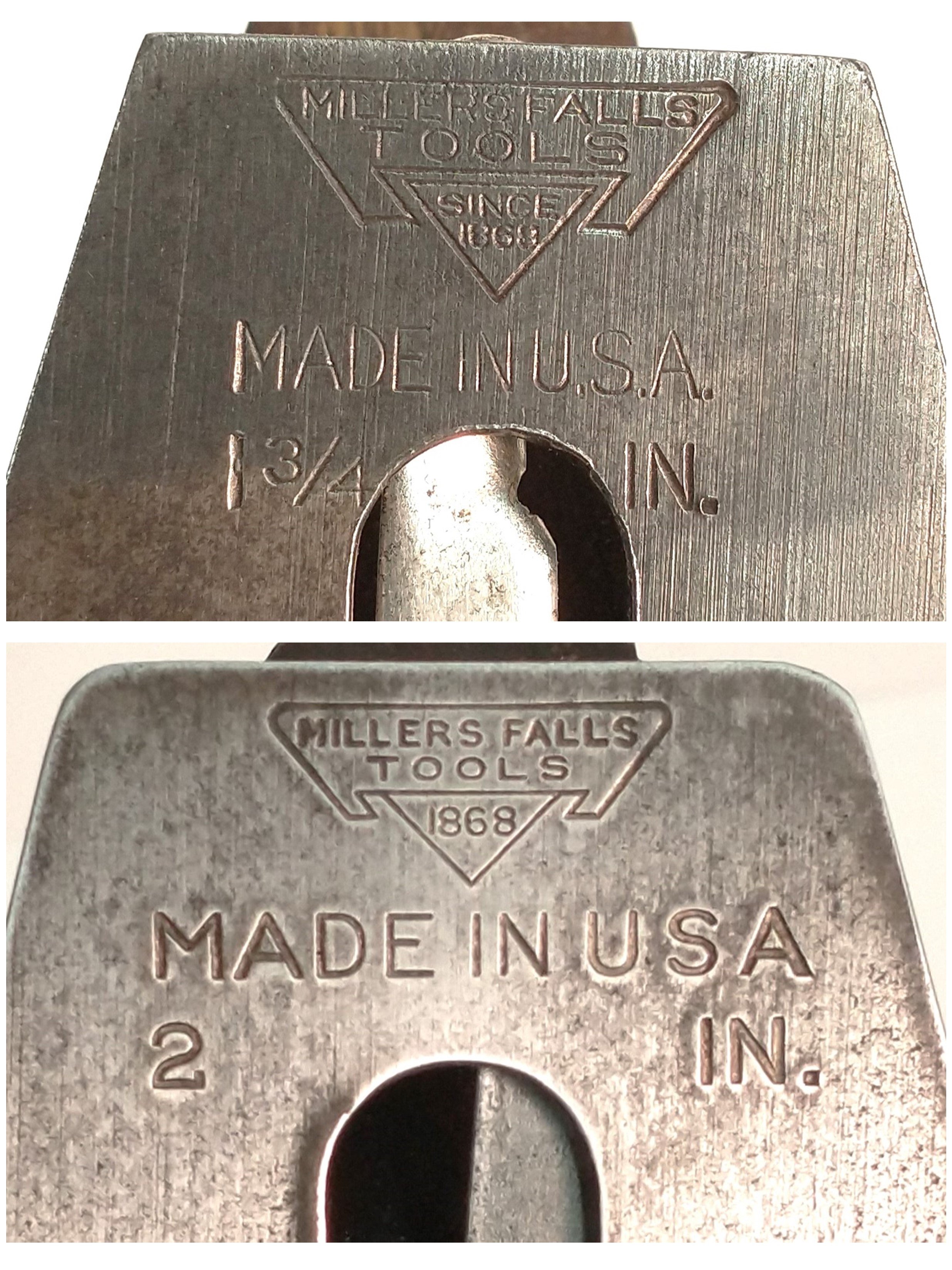

Iron trademark contains an isosceles trapezoid with words “Millers Falls Tools”

Iron trademark contains a triangle with the words “Since 1868”. The triangle does not touch the trapezoid.

Under the triangle are two lines with the words “MADE IN U.S.A.” and the iron size in inches.

Initial Release 2" configuration 1929 - 1931. Note the metal around the lever cap screw.

1-3/4" and 2" 1931 -1935 configuration. Extra metal was added around the lever cap screw

1-3/4", 2", 2-1/4 frog face. Early configuration on the 1-3/4" and 2". The 2-1/4" frog never changed during the type 1 years.

1-3/4", 2", 2-1/4 Back. Note the red cast iron yoke and the brass depth adjustment nut

Painted cast iron yoke

12-20 Flat fillister frog locking screws

The type 1 irons will have a triangle not touching the shape above it. Inside the triangle are the words "SINCE 1868".

Type 1

Body, Knob and Tote

A list of the 10 bodies with casting numbers and sole dimensions;

No. 7 (300) 7-3/4” x 1-15/16”

No. 8 (301) 8-3/4” x 2-1/8”

No. 9 (302) 9” x 2-1/4”

No. 10 (303) 10” x 2-7/8”

No. 11 (304) 11.5” x 2-1/8”

No. 14 (305) 14” x 2-1/4”

No. 15 (306) 15” x 2-3/4”

No. 18 (307) 17-7/8” x 2-7/8”

No. 22 (308) 21-3/4” x 2-7/8”

No. 24 (309) 23-7/8” x 3-1/8”

1929 to 1935 Common Features

Company Name cast into bed encircling the knob.

Plane number cast into the bed.

“MADE IN U.S.A.” cast into bed between frog seat and tote.

No. 8 and larger are configured with a frog adjuster screw. Only the No. 7 has no frog adjuster screw.

The heel tab on the No. 7, No. 8, No. 9 and No. 10 is raised above the sole.

The No. 8 and No. 10 through No. 24 have a raised tote receiver.

The No. 7 and No. 9 do not have a raised tote receiver.

High support rib

Cocobolo knob and tote secured with brass waist nuts with a 12-20 double threaded rod.

Cocobolo knob has six partial impressions where the knob was attached to the lathe.

Raised Heel Tab. Because the heel tab was raised on the type 1, the length of the sole did not include the heel tab.

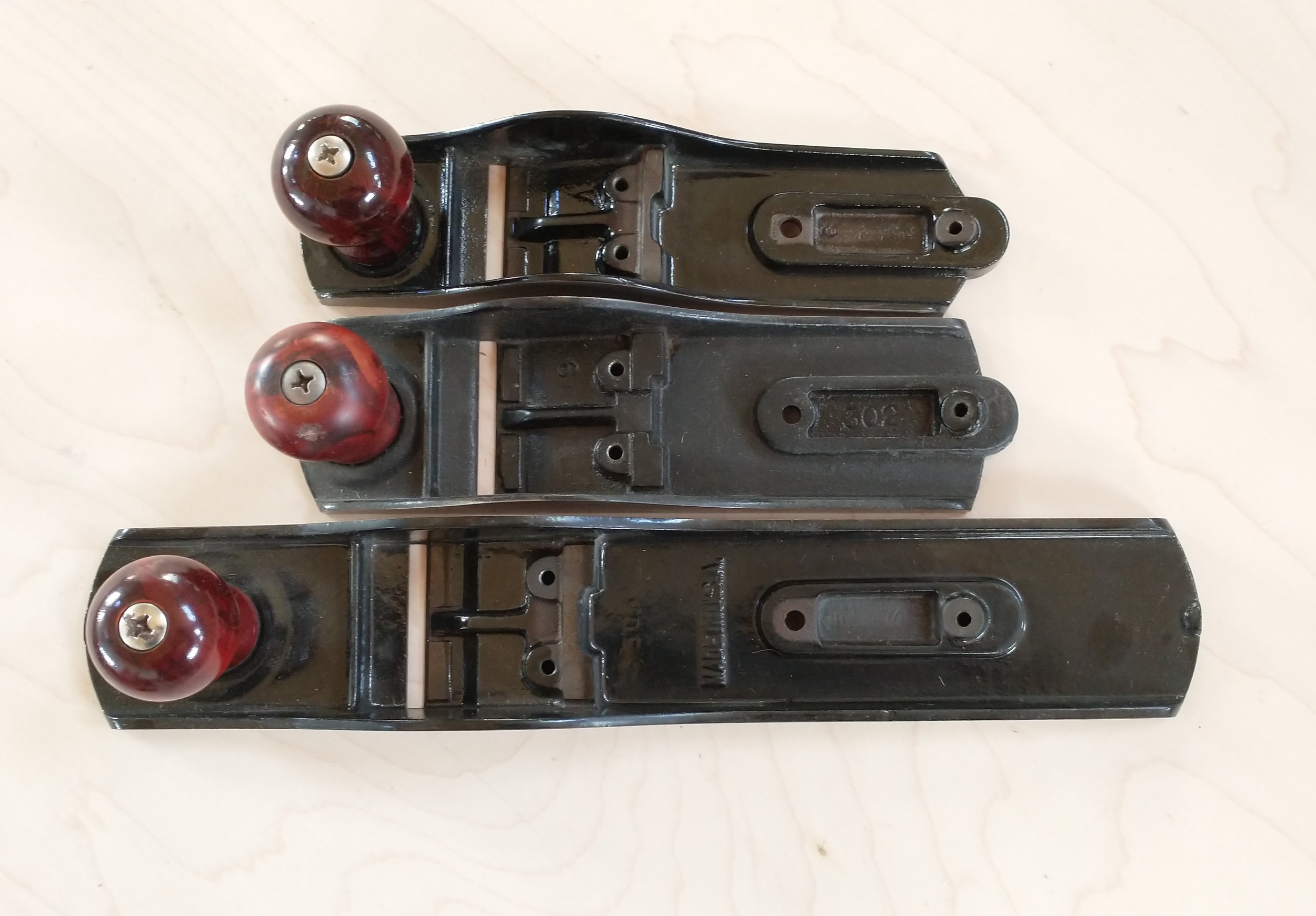

No. 14, No. 9, No. 8

Knob with Six Lathe Marks - Waist Nut/Threaded Rod - Cocobolo Wood

The type 1 knob has six partial groves on the bottom.

Type 1 Planes

The type 1 plane with the name and number cast into the bed and the small features outlined above make this plane worth adding to your collection.

No.8 Type 1

No. 24 Type 1

No. 10 Type 1

No.14 Type 1

Type 2

Lever Cap

1936 to 1941 Common Features

Two piece nickel plated hinged cap with three contact points.

Interlocking tabs on the main upper section eliminated but the lower T-section still used.

Semi-circle containing “MILLERS FALLS” with a red background of the semi-circle.

Back side of lower section contains free hand cast text “PAT. APLD. FOR”.

Large rivet head replaced with smaller rivet head securing cam lever spring.

Patent number 1822520 stamped on upper section face.

2” Only - Casting relief inside length is straight from curved shape.

From the front, the type 2 lever cap looks the same as the later type 1. The back is where you will see the changes. The cam spring is held on with a smaller head rivet. The locking tabs on the upper section have been eliminated.

Type 2

Frog and Iron

1936 to 1941 Common Features

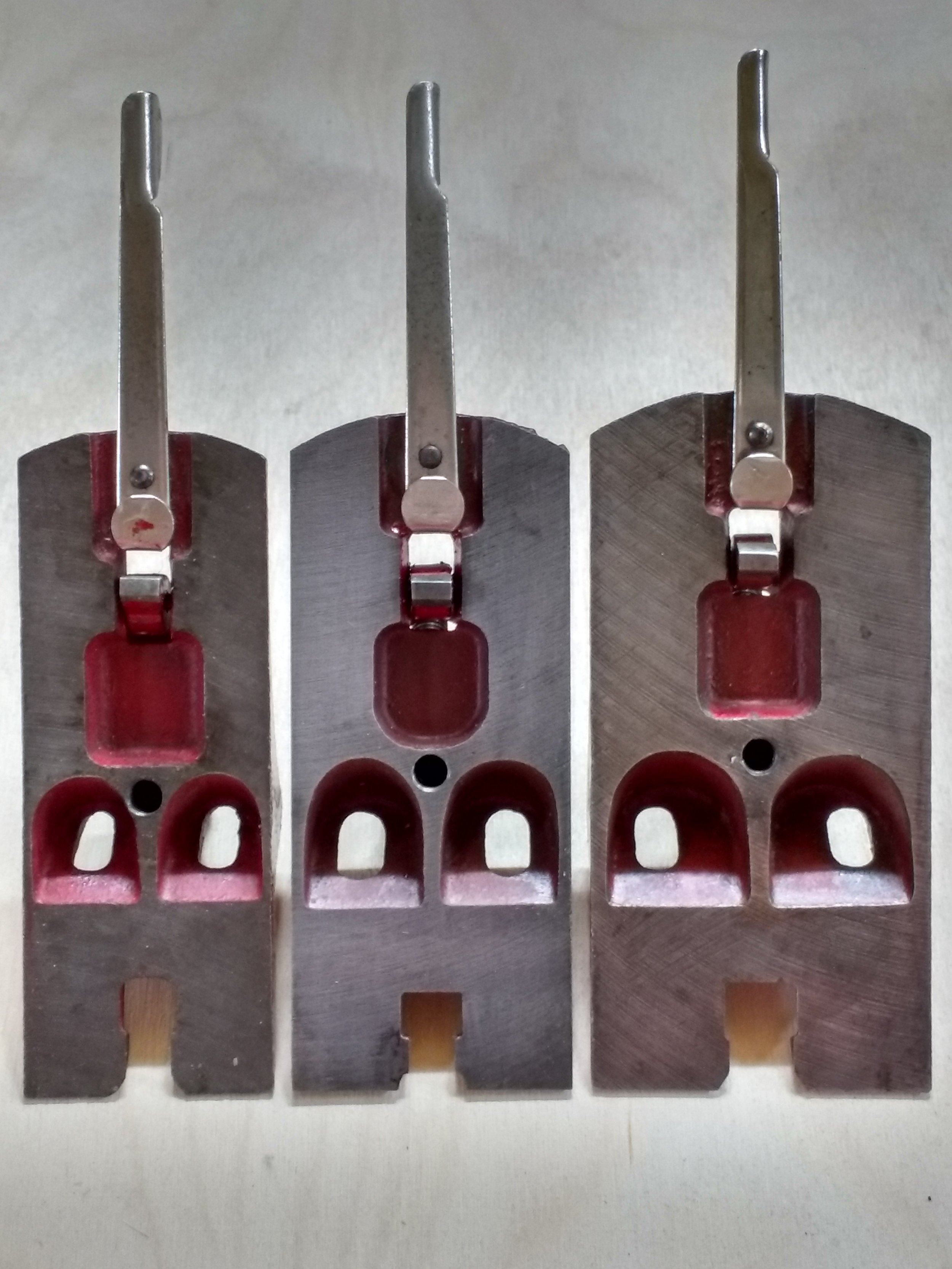

Painted red

Steel nickel plated yoke replaces cast iron yoke

Yoke pin recess added on either side of the yoke pin

Frog face relief added

Knurled 9/32-24 brass depth adjusting nut (recessed design)

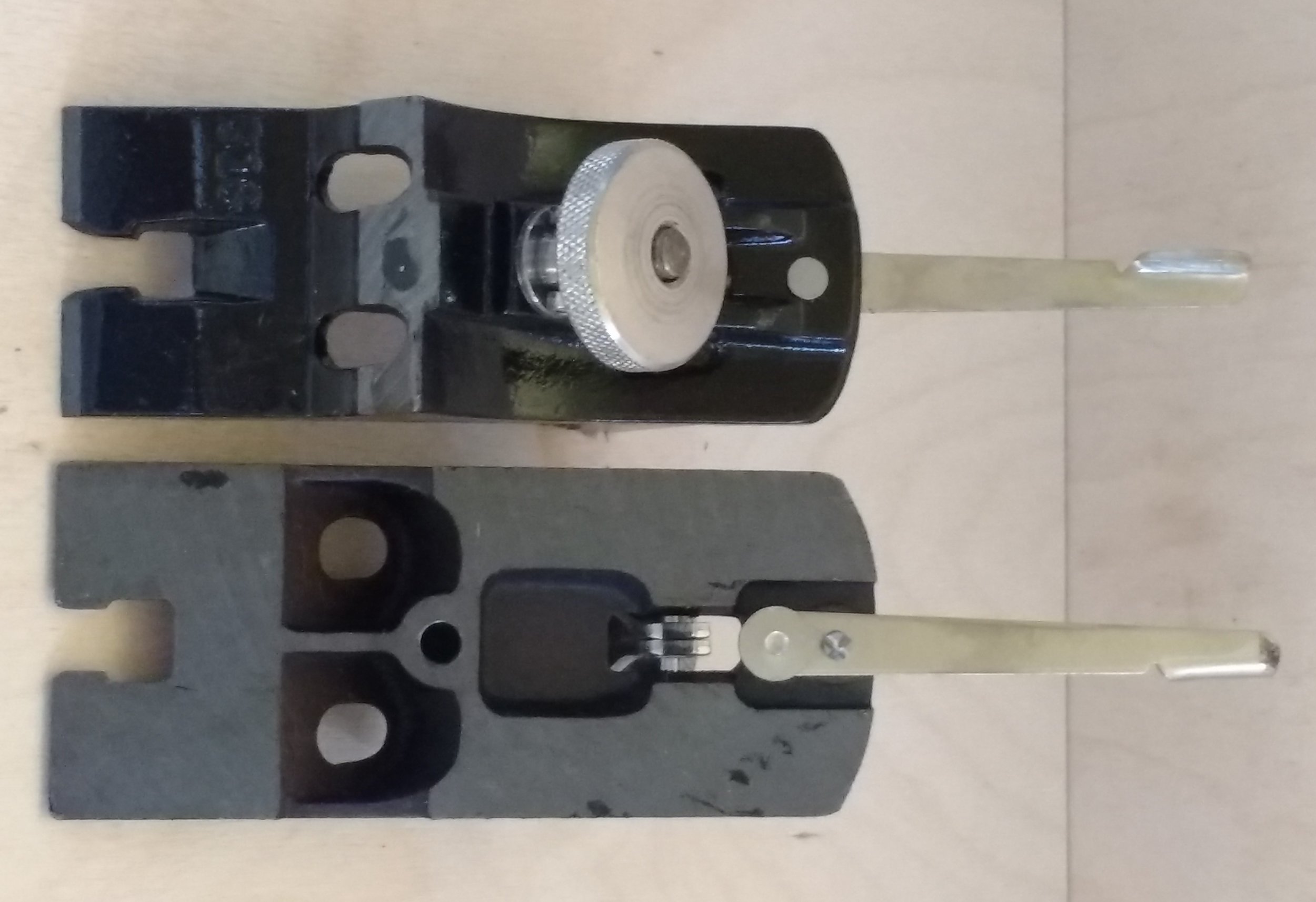

solid disk replaces the folded end of the lateral adjustment lever

1-3/4” and larger frogs are configured with a frog adjuster tab/screw. Only the 1-5/8” frog has no adjuster tab/screw.

extra metal around the lever cap screw on the 1-3/4” and 2”face only.

12-20 pan head frog locking screws replaces the fillister screw

Same iron trademark as the type 1 except USA and size are spread out.

Frog Face Relief - Steel Yoke - Disk Lateral Adjustment Lever

Yoke Pin Recess

12-20 Pan Head Frog Locking Screws

The early type 2 irons will have the triangle not touching the structure above it. Near the end of the type 2, the triangle only has "1868".

Type 2

Body, Knob and Tote

1936 to 1941 Common Features

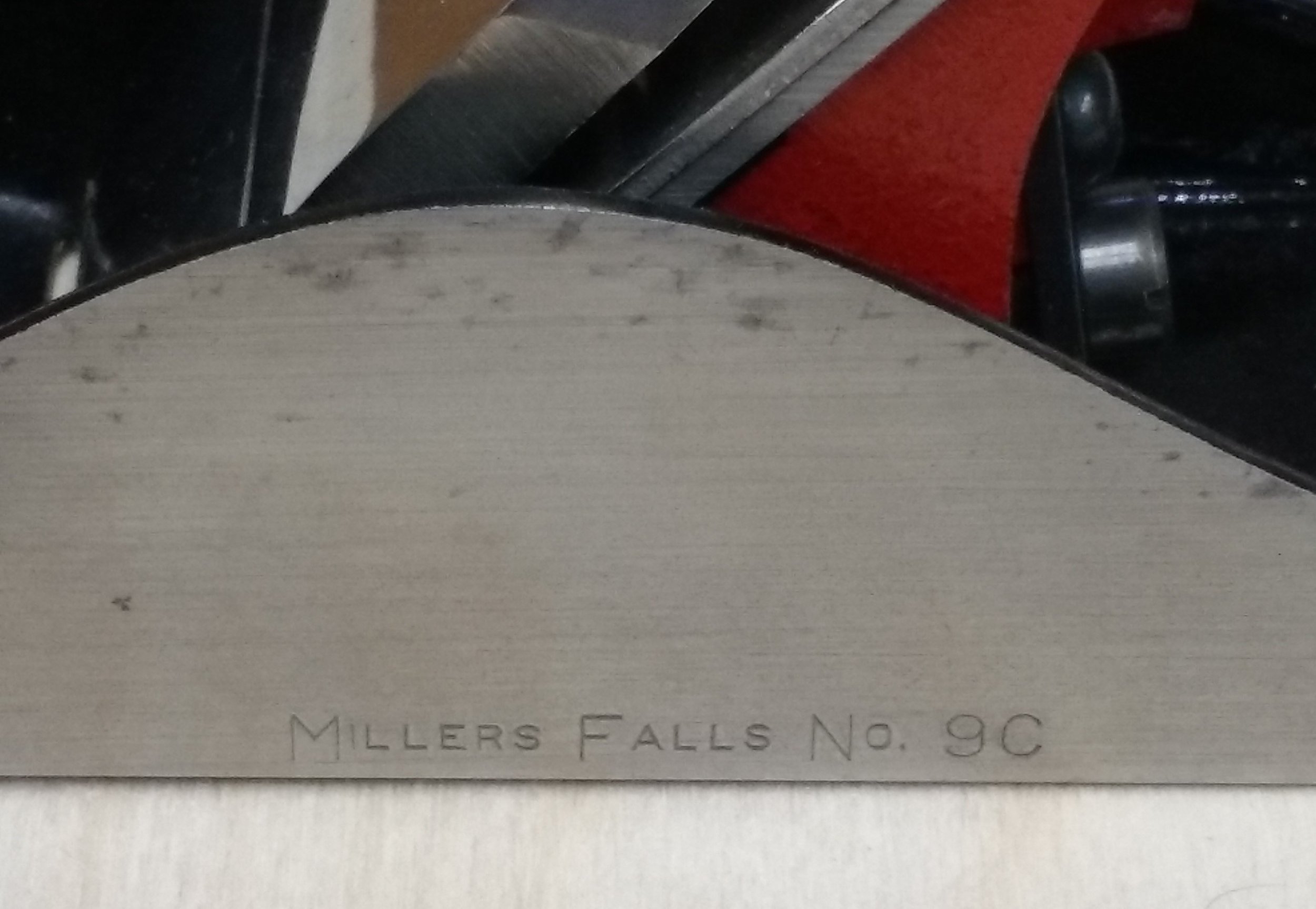

Company Name and model number removed from the bed and stamped on left cheek.

Bed Knob Ribs replaced smooth bed under the tote. These eight ribs will fit into the impressions on the knob.

“MADE IN U.S.A.” cast into bed between frog seat and tote.

No. 8 and larger are configured with a frog adjuster screw. Only the No. 7 has no frog adjuster screw.

The heel tab on the No. 7, No. 8, No. 9 and No. 10 are now part of the sole.

During the type 2 period, the raised tote receiver is removed from the No. 8.

The No. 10 through No. 24 have a raised tote receiver.

The No. 7 and No. 9 do not have a raised tote receiver.

Around 1938, a casting gate is seen on the toe and heel of the No. 11 through the No. 24

Lower support rib by the end of the type 2 period.

Cocobolo knob and tote secured with brass waist nuts and a 12-20 double threaded rod.

Cocobolo knob has eight full impressions where the knob was attached to the lathe.

Flush Heal Tab

Name and Number Cheek Stamp

Early Version without Casting Gates - Matching Eight Groves/Ribs

Later version with casting gates at the toe and heel. Eight ribs on the bed with matching groves on the bottom of the knob.

Later No. 11 Type 2 with a casting gate

Early No. 8 type 2 with a raised tote receiver. By the end of the type 2 period, the raised tote receiver will be eliminated from the No. 8 bed.

Type 2

Crossover Features

This no. 15 type 2 has a type 1 lever cap and a type 1 frog. The No. 15 more than any other model will see these transition parts.

This type 2 No. 8 has a type 1 lateral adjustment lever with the folded end.

Type 2 Planes

The type 2 plane with the cocobolo knob/tote and the name and number stamped on the left cheek. With a production period of only six years, these could be hard to find.

No. 7 Type 2

No.9 Type2

Type 3

Lever Cap

1942 to 1948 Common Features

Two piece nickel plated hinged cap with three contact points.

No interlocking tabs on the main upper section.

Semi-circle containing “MILLERS FALLS” in a semi-circle.

No paint in semi-circle

Back side of lower section contains free hand text “PAT. APLD. FOR”.

Smaller rivet head securing cam lever spring.

Patent number 1822520 stamped on upper section face.

2” Only - Casting relief inside length is straight.

There were changes made to only the 2” lever cap around 1944.

2” Only - The casting number was changed from 334A to 334.

2” Only - Paint was added to the semicircle with the 334 casting number.

2” Only - “PAT. APLD. FOR”. was eliminated with the 334 casting number.

Early 2" Type 3 lever cap with a 334A casting number and the "PAT APLD FOR" message

Later 2" Type 3 lever cap with a 334 cast number without the patent message. This change only happened on the 2" lever cap which were on the No. 9 and No. 14.

Type 3

Frog and Iron

1942 to 1948 Common Features

Painted red

Steel nickel plated yoke

Yoke pin recess

Frog face relief

Knurled 9/32-24 nickel depth adjusting nut (recessed design) , replaces brass adjusting nut

The depth adjustment nut can have a blued finish

Solid disk on the end of the lateral adjustment lever

1-3/4” and larger frogs are configured with a frog adjuster tab/screw. Only the 1-5/8” frog has no adjuster tab/screw.

12-20 pan head frog locking screws

Early iron trademark has the triangle containing only “1868”

The iron trademark, the triangle is touching the trapezoid.

2” Only - The casting number was changed from 317 to 496A round 1944.

During the type 3 years, only the 2" frog found on the No. 9 and No. 14 planes changed the casting number from 317 to 496A. Planes found with 317 casting numbers are early type 3 production and 496A numbers are later type 3 production. Also note the blued depth adjusting nut found on some type 3 planes

The type 3 irons will have a triangle touching the shape above it. Inside the triangle are the words "SINCE 1868". Some early type 3 irons will only have the date "1868" inside the triangle.

Type 3

Body, Knob and Tote

1942 to 1948 Common Features

Company Name and model number stamped on left cheek.

Knob bed ribs

“MADE IN U.S.A.” cast into bed between frog seat and tote.

No. 8 and larger are configured with a frog adjuster screw. Only the No. 7 has no frog adjuster screw.

The heel tab on the No. 7, No. 8, No. 9 and No. 10 is part of the sole.

The No. 7, No. 8 and No. 9 smoothing planes do not have a raised tote receiver.

The No. 10 through No. 24 have a raised tote receiver.

Casting gate is seen on the toe and heel of the No. 11 through the No. 24

Low support rib

No. 7 eliminated by 1944.

Stained hardwood knob and tote replace cocobolo knob and tote

One piece 12-20 slotted bolt replaces brass waist nuts with double threaded rod .

The easiest way to identify a type 3 bench plane is by the hardwood Tote/Knob with a one piece steel bolt. The stain on the wood would show lighter on the long grain and darker on the end grain. The one piece bolt was only used during the type 3 and type 5 years.

Type 3

Crossover Features

This plane has a "Solid Tool Steel" trademark iron which is not the expected iron for this type. There are two reasons this can happen; this is a crossover plane at the end of the type 3 period, or the iron was replaced. Look for a date in the box to help make that determination. Other features on the plane are a steel bolt securing the knob and the lack of paint around the Millers Falls on the lever cap.

Type 3 Planes

The type 3 plane has the district stained knob/tote. During the war, Millers Falls made a lot of these planes in this type. Look for planes with the original finish.

No. 9 Type 3

No.22 Type 3

Type 2 Second Release (Alt Type 4)

Lever Cap

1949 to 1952 Common Features

Two piece nickel plated hinged cap with three contact points.

No interlocking tabs on the main upper section.

Semi-circle containing “MILLERS FALLS” in a semi-circle.

Red paint in semi-circle

Back side of lower section contains free hand text “PAT APLD. FOR”.

Smaller rivet head securing cam lever spring.

Patent number 1822520 stamped on upper section face.

2” Only - “PAT APLD. FOR”. was eliminated with the 334 casting number.

Type 2 Second Release (Alt Type 4)

Frog and Iron

1949 to 1952 Common Features

Painted red

Steel nickel plated yoke

Yoke pin recess

Frog face relief

Knurled 9/32-24 brass depth adjusting nut (recessed design) replaces nickel adjusting nut

Solid disk on the end of the lateral adjustment lever

Frog adjuster tab/screw.

12-20 pan head frog locking screws

A new trademark has the words “SOLID TOOL STEEL” above a trapezoid like shape containing “MILLERS FALLS”

A new trademark has an empty triangle under the trapezoid like shape with “MADE IN USA” on either side of the triangle.

2” Only- The casting number is 496A.

Solid Tool Steel Iron

Type 2 Second Release (Alt Type 4)

Body, Knob and Tote

1949 to 1952 Common Features

Company Name and model number stamped on left cheek.

Knob bed ribs

“MADE IN U.S.A.” cast into bed between frog seat and tote.

Frog adjuster screw. No. 7 eliminated in 1944.

The heel tab on the No. 8, No. 9 and No. 10 is part of the sole.

The No. 8 and No. 9 smoothing planes do not have a raised tote receiver.

The No. 10 through No. 24 have a raised tote receiver.

Casting gate is seen on the toe and heel of the No. 11 through the No. 24

Low support rib

Cocobolo knob and tote secured with brass waist nuts and a 12-20 double threaded rod replace hardwood and single bolt.

Type 2 Second Release

Crossover Features

This plane has all the features of a type 2 second release except the cocobolo knob and tote were drilled for the remaining type 3 bolts.

This is a No. 14 type 2 second release with a Since 1868 trademark iron. It is easy to identify the 2" type 2/2 planes because of the casting number changes on the lever cap and frog during the type 3 years.

Type 2 Second Release Planes

How do you distinguish this type from the original type 2? The 2” planes are easy with the casting numbers on the lever cap and frog. For the others, look for casting gates, Solid Tool Steel iron and be aware that the original version did not stamp the casting number on the body.

No. 9 Type 2 Second Release

No. 11 Type 2 Second Release

Type 4 (Alt Type 5)

Lever Cap

1953 to 1965 Common Features

Two piece nickel plated hinged cap with three contact points.

No interlocking tabs on the main upper section.

Semi-circle containing “MILLERS FALLS” in a semi-circle.

Red paint in semi-circle

Back side of lower section contains free hand text “PAT APLD. FOR”.

2” Only - “PAT APLD. FOR”. was eliminated with the 334 casting number.

Smaller rivet head securing cam lever spring.

Patent number 1822520 stamped on upper section face.

Cam lever spring has two sharper bent edges.

Metal was removed between the cam lever spring bottom and the casting relief.

2” - “PAT APLD. FOR” with casting number 334A was used on a limited number of caps

This is a type 4 2-3/8" lever cap. New features are the sharper bend in the cam lever spring and the reduced metal between the spring and the casting relief. It is hard to see in this picture the "PAT. APLD. FOR" and the casting number 336.

Both of these lever caps are 2" found on the No. 9 and No. 14. The cap on the left is a typical type 4 cap without the "PAT. APLD. FOR" that was eliminated when the casting number changed from 334A to 334 around 1944. Late near the end of the type 4 period, Millers Falls brought back the bottom half of the 334A and applied it to the type 4 upper half shown on the lever cap to the right.

Type 4 (Alt Type 5)

Frog and Iron

1953 to 1965 Common Features

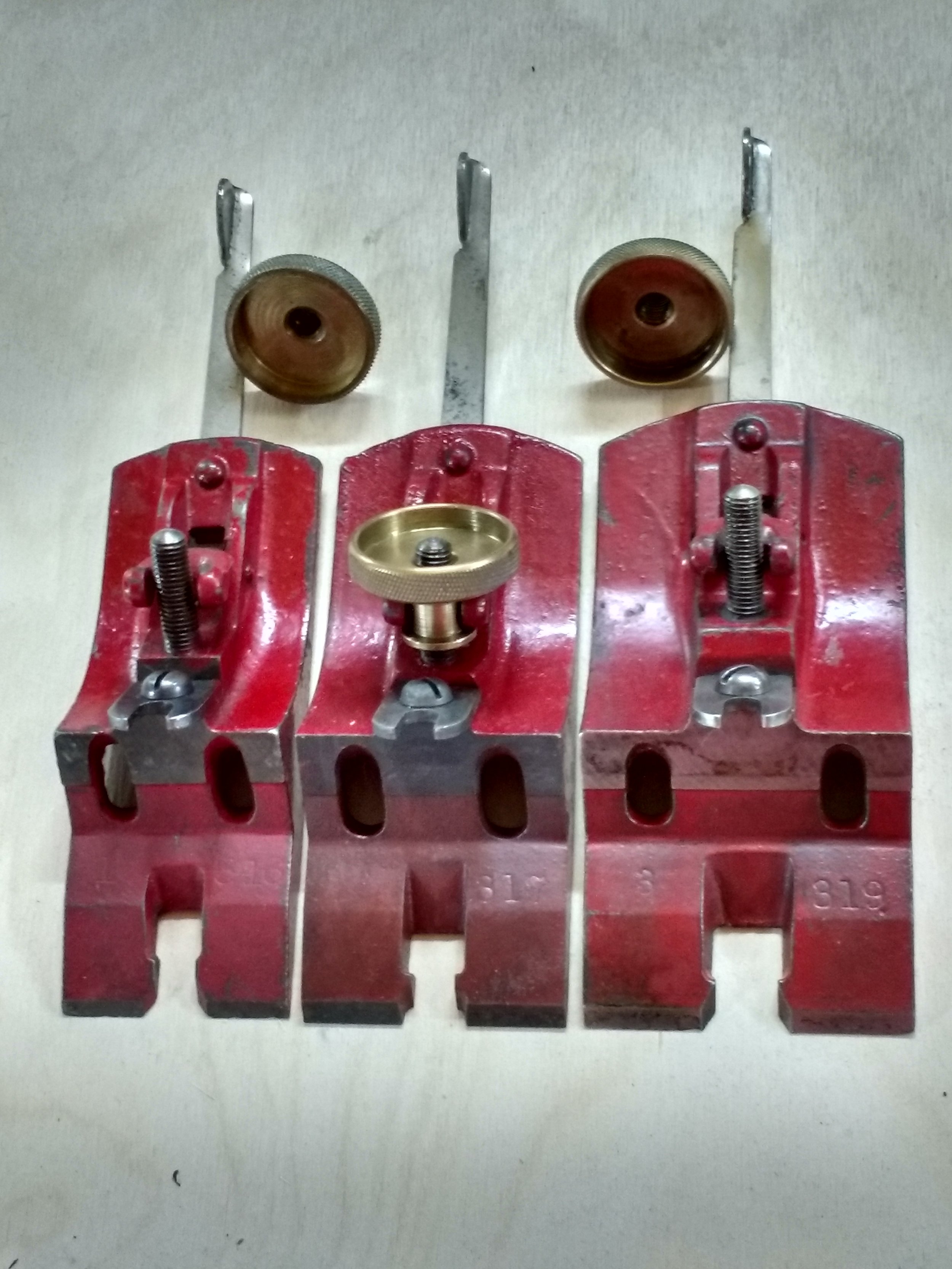

Black paint replaces the red paint.

Steel nickel plated yoke

Yoke pin recess

Frog face relief

Knurled 9/32-24 brass depth adjusting nut (full design) replaces recessed adjusting nut

Solid disk on the end of the lateral adjustment lever

Frog adjuster tab/screw.

12-20 fillister frog locking screws replaces the pan head screw

“SOLID TOOL STEEL” iron

2” Only - The casting number was changed from 496A to 496 between 1/58 and 10/58.

Full Depth Adj Nut - Black Paint - 496A to 496(2")

Fillister Frog Locking Screws

Type 4 (Alt Type 5)

Body, Knob and Tote

1953 to 1965 Common Features

Company Name and model number stamped on left cheek.

Knob bed ribs

“MADE IN U.S.A.” cast into bed between frog seat and tote.

Frog adjuster screw. No. 7 eliminated in 1944.

The heel tab on the No. 8, No. 9 and No. 10 is part of the sole.

The No. 8 and No. 9 smoothing planes do not have a raised tote receiver.

The No. 10 through No. 24 have a raised tote receiver.

Casting gate is seen on the toe and heel of the No. 11 to the No. 24

Low support rib

No. 10, 10C, 15, 15C, 24 and No. 24C eliminated by 1961.

Goncalo knob and tote secured with brass waist nuts and a 12-20 double threaded rod replaces the cocobolo wood.

Shorter horn on larger planes. standard size horn on finishing planes.

Goncalo Knob/Tote - The jack, fore and jointer planes had a shorter horn. The finishing planes had a standard horn that was found on the totes from previous types. Shown is a No. 14 on the left and a No. 8 on the right.

Type 4

Crossover Features

This is a type 4 No. 14 plane with two crossover parts. The first is the recessed depth adjusting nut and the second is the type 2 second release lever cap without the metal removed between the cam spring and the casting relief. The cam spring on this cap is a type 4 with the two sharper bends. The type 4 planes were released in 1953. The box this plane was in had a 4/1953 date.

Type 4 Planes

The type 4 timespan was the longest of the six type periods. It is also what I consider the last type produced with a quality expected of a premium plane. The only fault I see in this plane is the finish they selected for the tigerwood. The wood itself was a great choice, and the finish applied out of the factory made for one good looking plane. The problem is if the finish is damaged, it is very difficult to bring it back. This is a great plane to collect and use. If the finish is damaged, maybe someone out there has the orange touch.

No. 9 Type 4

No. 8 Type 4 - Note the finish has flaked off the knob.

Type 5 (Alt Type 6)

Lever Cap

1966 to 1978 Common Features

One piece nickel plated cap replaces hinged two piece cap.

No patent number stamped on the front.

Semi-circle containing “MILLERS FALLS” in a semi-circle.

No paint in semi-circle

Smaller rivet head securing cam lever spring.

Cam lever spring bend has two sharper edged.

Later production, cam lever spring eliminated

One piece Lever cap without paint

Cam Lever Spring Eliminated

Type 5 (Alt Type 6)

Frog and Iron

1966 to 1978 Common Features

Black paint

Steel nickel plated yoke

Yoke pin recess

Frog face relief

Knurled 9/32-24 nickel depth adjusting nut (full design) replaces brass adjusting nut

Solid disk on the end of the lateral adjustment lever

Frog adjuster tab/screw eliminated

later production, metal eliminated between cap iron screw recess and frog locking screw slots

12-24 Phillips fillister head frog locking screws replaces 12-20 beveled fillister head screws

Early production - Ink stamp seen on iron.

No pressure or ink stamp on iron.

Iron shorten by reducing the chip breaker screw slot from 4-5/8” to 3-5/8” slot.

Nickel Depth Adj Nut - No Frog Adj Tab

Later Outsource Version

The type 5 irons had a shorter chip breaker screw slot. The cutting end of the iron stayed the same length.

12-24 Frog Locking Screws

Type 5 (Alt Type 6)

Body, Knob and Tote

1966 to 1978 Common Features

Company Name and model number stamped on left cheek.

Knob bed ribs

The heel tab on the No. 8 and No. 9 is part of the sole.

Casting gate is seen on the toe and heel of the No. 11 through the No. 22.

Low support rib

“B” added to model number cheek stamp

No. 8CB renamed No. 8-03-B in 1968/1969. No. 8B and No. 8-03-B eliminated by 1971.

No. 9CB renamed No. 9-02-B in 1968/1969. No. 9-02-B eliminated by 1971, 9B by 1976.

No. 11B eliminated by 1970

No. 14CB renamed No. 14-01-B in 1968/1969. No. 14-01-B eliminated by 1971, 14B by 1978.

No. 18CB eliminated by 1967, 18B by 1971.

No. 22B, 22CB eliminated by 1967

“MADE IN U.S.A.” stamped into bed between frog seat and tote on bodies under 14 inches.

“MADE IN U.S.A.” cast into bed between frog seat and tote on bodies 14 inches and larger.

Frog adjuster screw eliminated

Raised Tote Receiver added to the No. 8 and No. 9.

All planes have the same sized raised tote receiver.

Tote screw eliminated. replaced with a pin.

No. 8 and No 9 cast front tote anchor replaced with a pin.

Later production, metal eliminated in the middle of the upper frog seat.

Goncalo knob and tote secured with steel 12-24 one piece Phillips head bolts replaces waist nuts with 12-20 double threaded rod.

The same tote can be used on all premium planes

This is some of what you will see on a outsourced body. The pin hole for the tote toe, the USA stamped, no frog adjuster screw, and the metal eliminated from the upper frog seat

Steel One Piece 12-24 Phillips Bolts. All totes will have a Toe Tote Pin

This picture shows the standard raised tote receiver used on all type 5 planes. From the No. 8 to the No. 22, the raised tote receiver did not change in size. This allowed the company to make only one size tote that would fit on any of the existing type 5 bench planes.

From 1929 until around 1964, the model number in the catalog matched the stamp on the cheek. In 1964, starting with the secondary line, a “B” was added to only the cheek but not the catalog and eventually this would carry over to the type 5 premium line. In 1968, because of multiple tools in the catalog with the same model number (yes there were three No. 9 tools), the No.8, 9 and 14 corrugated bench planes fell victim to this identity crisis and were given a unique name in the form of a dash number. Don’t look for the “B” in the catalog.

Type 5

Crossover Features

This No. 22 transition plane has the type 4 body/knob/tote and iron with a type 5 lever cap. The type 5 lever cap has a type 4 patent stamp.

The No. 18 has a type 4 body with brass waist nuts and a Solid Tool Steel type 4 iron. The lever cap is a type 5.

This No. 14 has some interesting crossover features. The body was a type 4 and was tapped for the original 7/32-24 threads to secure the frog, knob, and tote. The tote is a type 4 because of the short horn, tote screw, and the brass waist nuts. The frog was probably a type 4 with the original brass adjusting nut. What makes the body and frog a type 5 is the frog adjuster screw and the frog adjuster tab were not included on this plane. The lever cap is clearly a type 5.

This type 5 has the type 5 features in the raised tote receiver, one piece lever cap and the Philips knob/tote bolts. The parts from the previous version are the Solid Tool Steel trademark iron and the brass depth adjusting nut.

Type 5 Planes

At the start of the type 5 years, six of the premium planes were still being produced. By 1971 the number would be down to two.

This No. 8 was produced near the start of the type 5 period. This plane was not as good as the previous types, but with a little tuning, it was a good plane.

This No. 9 was cast outside of the Greenfield plant. When you cut back on quality, the end is right around the corner.

Outside The Type Study

The following pictures will show features on some Millers Falls planes that are outside a transition change from one type to another.

No. 15 type 2 with no yoke pin recess. This casting has a mix of type 1 and type 2 features. It's not clear if this frog was a leftover type 1 frog without the yoke pin recess and a frog face relief was machined on it.

The face of the No. 15 frog looks like a type 2 with a folded lateral adjuster. The folded lateral adjuster is common on the No.209 and rebranded planes. The lack of the yoke pin recess is unusual in the type study.